= ASTRONAUTICAL EVOLUTION =

Issue 119, 1 November 2015 – 46th Apollo Anniversary Year

| Site home | Chronological index | About AE |

“Drowning in Process”

The great space slowdown

I’ve always found it hard to understand exactly why NASA’s rocket and spacecraft building programmes are so much slower and costlier today, after half a century’s accumulated experience, than they were in the glory days of the 1960s.

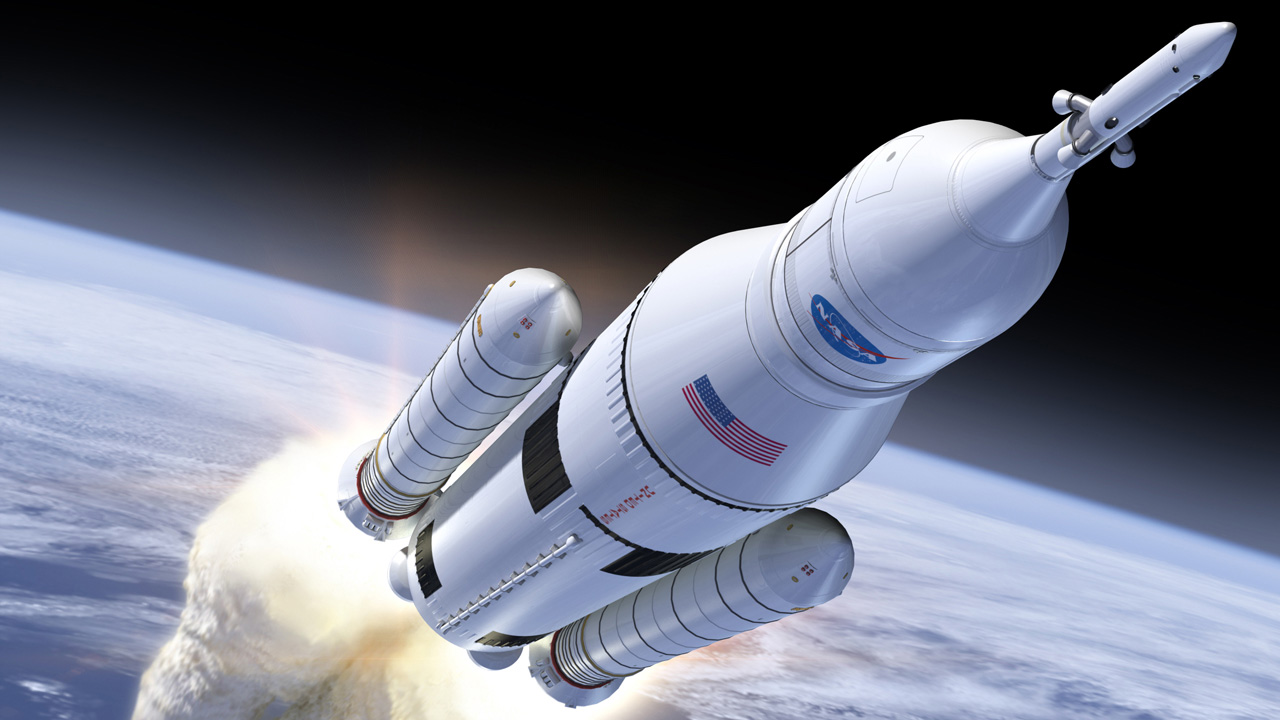

Case in point: the Orion spacecraft was announced in 2004 (then called the Crew Exploration Vehicle) as part of the younger President Bush’s Vision for Space Exploration. Its first unmanned flight test came ten years later, and it is not expected to fly with a crew until the early 2020s, almost two decades after programme start, and still without any accompanying deep-space habitat or lunar/martian lander to enable it to complete a mission beyond Earth orbit.

During an earlier comparable period of two decades, NASA went from flying the Mercury capsule to flying the Space Shuttle.

Insight from an insider

Wayne Hale has been describing some of the problems of doing space engineering at NASA. With his 32 years of experience at NASA before his retirement, including positions as Space Shuttle Program Manager or Deputy Manager for 5 years and Space Shuttle Flight Director for 40 missions, he has an intimate acquaintance with what it takes to get into space.

Three blog posts of his particularly caught my attention (and many of his former colleagues have added interesting points in the comments):

- How to Avoid Train Wrecks (5 Oct. 2015)

- The coming train wreck for Commercial Human Spaceflight (14 Nov. 2010)

- Standards (4 Nov. 2011)

Some extracts from his latest post:

“Spaceflight is exacting and very hard; the environments are tough, the energy levels are extreme, and the margin between success and failure is very slim. All of this is said so often that is sounds like a trite cliché. But no matter how trite it sounds, it is true. In the 21st century, still true.”

But engineers have learned bit by bit from the failures early in the space age:

“The point is, success in spaceflight is not easy and comes at a high price because the work is exacting and unforgiving. But we know how to do it well. Just follow the process.

But there is a rub, because the process, the standards, are not static. They are always being improved. Added to. Never reduced, unfortunately.”

The Columbia disaster provided the impetus to add a lot more process, until:

“I have a cheap seat view of the Orion/SLS development. My basic observation: those efforts are drowning in ‘process’. The biggest threat to their success is not technical; it is schedule and cost.”

But:

“The secret of a good program – as a very senior spacecraft designer once told me – is knowing how much is enough and then not doing anything more.”

Engineering fantasy versus engineering reality

In a nutshell: imagine a curve of reliability against cost. The more a project costs means the more people are working on it, the more detail is being documented about every part, the more ground testing of individual parts and subsystems is being done, the tighter technical standards become, the slower and more laborious the processes of design, manufacture and assembly, with ever more checking and double-checking of every step…

Clearly, up to a point this works! Quality assurance is what got Apollo-Saturn to the Moon – and lack of it is what doomed the Soviet Moon rockets to a series of ignominious explosions and crashes.

But the assumption which an institution like a space agency inevitably adopts is that more cost always means better quality and more reliability. (Probably in much the same way as a government assumes that more legislation always gets it ever closer to the perfect society.) It then becomes a matter of simply driving up the cost and slowing down the schedule to the point that the quality and reliability become arbitrarily close to perfection. Wayne Hale:

“Right now, inside NASA, we have trained our workforce to do it perfectly. And perfection is very costly and takes a long time.”

In his 2010 post, this took the following form:

“Now NASA has released a draft (dated Oct. 8, 2010) of its requirements CCT-REQ-1130 ISS Crew Transportation and Services Requirements. I’d like for you to read it but it is behind NASA’s IT firewall and you must have an ID and password to access it. I have read it and I’m disappointed. The document runs a mind-numbing 260 pages of densely spaced requirements. Most disappointing, on pages 7 to 11 is a table of 74 additional requirements documents which must be followed, in whole or in part. Taken all together, there are thousands of requirement statements referenced in this document. And for every one NASA will require a potential commercial space flight provider to document, prove, and verify with massive amounts of paperwork and/or electronic forms. This, folks, is the old way of doing business. This is one of the major reasons why spaceflight is as costly as it is.”

But clearly the reality is different. There comes a point of cost, of effort, of documentation, of quality assurance, of careful, methodical work, where adding more cost, more effort, more paperwork, more quality checking, more care is counterproductive. The reliability–cost curve has a hump in it. Going over the hump, the downside of further improvements begins to predominate over their upside.

The slower the schedule means the fewer the actual flights, and only a real flight can properly put a flying machine to the test, as aircraft designers have long known. The closer engineers are constrained by a process set out in detail in the documentation, the more they rely on following their instructions blindly and the less on their own engineering talent and common sense. It becomes progressively harder for any one person to see what’s going on. Design changes become progressively more difficult, the status quo ever more entrenched. Consider SpaceX’s effort to recover their Falcon first stages on a barge, and compare that with the fact that in 30 years the Shuttle never attempted to upgrade its solid boosters to allow a soft, dry landing, or to save its external tank for use in orbit.

Wayne Hale again:

“Most engineering problems have an optimum solution, a point where doing more actually results in less performance. This situation is not an exception.

Somebody needs to be able to just say no. In order to succeed.

It’s not really rocket science, it’s just good engineering.”

There is no engineering perfection, nor is there such a thing as 100.000% reliability or safety. Or, as Rand Simberg put it in the title of his recent book, Safe Is Not an Option.

We have to accept that there will continue to be occasional spaceflight disasters, just as there have been in all transport systems – on the roads, the railways, in shipping and in aviation. Making progress means learning from these disasters without overburdening the industry with so much extra process that it grinds to a halt.

Ironically, the excessive quality assurance applied to NASA’s manned spaceflight programme goes hand in hand with inadequate overall project design. Like the Apollo architecture on which it is based, the overall programme is incapable of either political or economic sustainability, and is therefore designed at the outset for eventual cancellation.

Even an optimally engineered Orion/SLS would be an inefficient use of resources, and the gold-plated one actually being built is even more wasteful. But given its short-sighted political origin, that should perhaps not come as a surprise.

Please send in comments by e-mail.

Interesting and relevant comments will be added to this page.

| Site home | Chronological index | About AE |